Deseja mudar o idioma?

¿Quieres cambiar tu idioma?

BONFIO RETARDANTE A CHAMA is a sewing thread produced with 100% Meta-Aramid fiber indicated for sewing in safety garments that come into contact with heat, fire and electric arc.

This product has, as its main feature, the high thermal resistance, withstanding temperatures above 260°C and being effective against heat and sudden fire. The BONFIO’s Meta-Aramid yarn has two internacional certifications: the UL Certificate (Underwriters Laboratories), one of the most recognized seals worldwide, which attests to compliance with the strict safety and quality standards of United States, Canada and Europe; and the certification according to ABNT, which regulates the requirements for protective clothing in Brazil. These certifications position BONFIO as the only nacional manufacturer that attends to the rules of ISO and NFPA at the same time, ensuring the highest requirement levels in protective clothing and other PPE, such as gloves and footwear.

BONFIO RETARDANTE A CHAMA also stands out for being a sewing thread with high performance lubrification and for using “Splicers” in your process, ensuring the quality of American technology and differentiating the product in the market.

The performance lubrification and "Splicers" are innovative processes, with BONFIO being one of the only companies in Brazil to use these technologies.

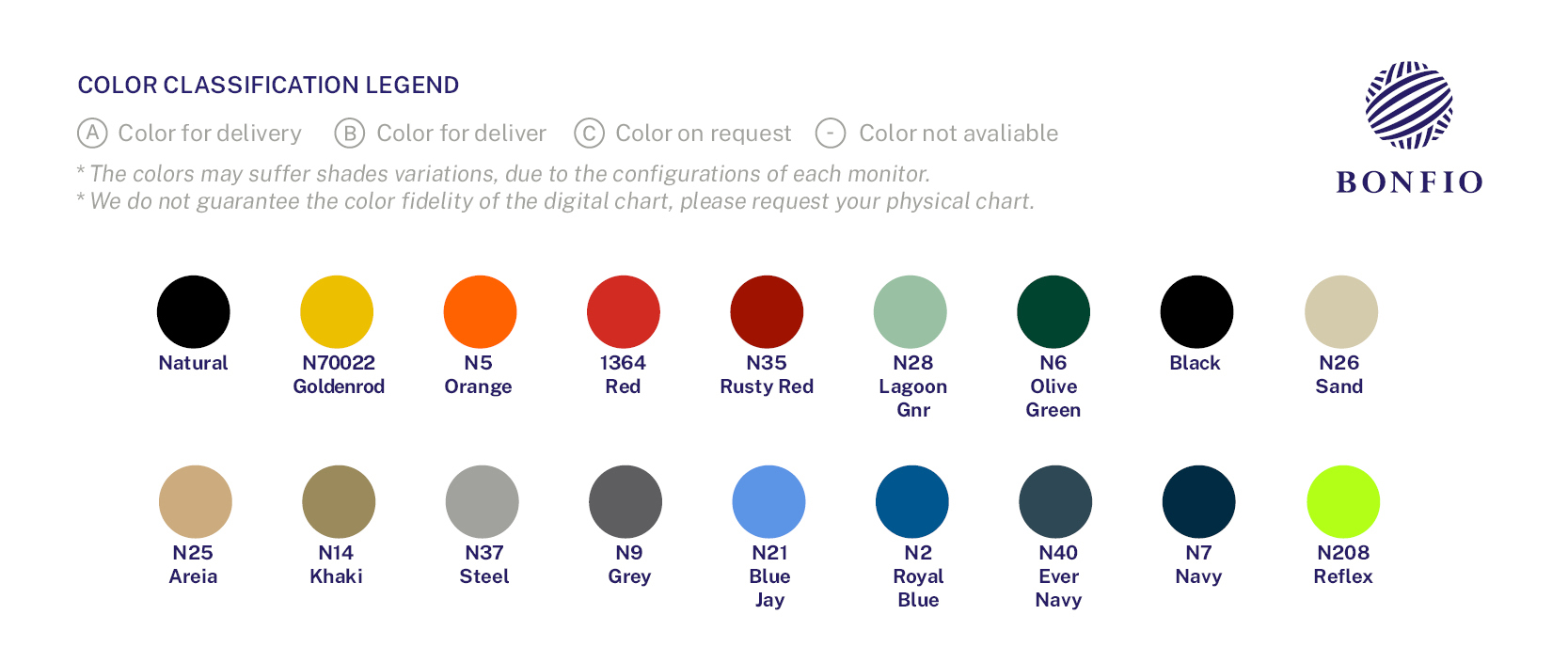

BONFIO RETARDANTE A CHAMA counts has a wide variety of colors, thus making the product highly competitive and versatile for the national and international markets.

BONFIO RETARDANTE A CHAMA

In order to perform well, BONFIO products must be well cared for, monitored and stored avoiding degradation due to mold, dirty, clarity and moisture. In addition, their incorrect warehouse directly impacts on sewing performance. Lack of space, time, misplaced labels and damaged packaging can prejudice the storage caution:

Instructions for extending durability:

• Always keep the packages closed;

• Remove from the storage according the necessity;

• Large labels easy to read helps the comprehension;

• Don´t put food near because them could be attract animals and stain them;

• Check possible damages in the packages that have been stored for a longer time;

• Avoid the direct lighting, natural or artificial on products.

Local suggested:

• Clean and free of dust;

• To colaborate with the access, we recomended a warehouse near from the fabric;

• Avoid a polluted place. The presence of gases can yellowish white tones;

• In addition to the light, excessive temperatures and relative humidity could be damage products, making them to lose strength, the white ones turn yellow and colored being fade.

Reccomended environmental conditions:

• Temperature between 15˚C and 25˚C (50˚F and 77˚F);

• Humidity between 40% and 60%;

Following all those guidelines, the useful life cycle of the products can be extended.